Stainless Steel 316TI Forged Bars

Ferrobend has a robust quality control process in place to ensure that every Stainless Steel 316TI Forged Bar meets the highest standards. This includes comprehensive testing for dimensional accuracy, surface finish, mechanical properties, and corrosion resistance. Non-destructive tests, such as ultrasonic testing and magnetic particle testing, are also performed to detect any internal defects that could compromise the integrity of the material.Read More

Stainless Steel 316TI Forged Plates

Ferrobend utilizes state-of-the-art forging techniques to transform the raw material into forged plates. Forging is a manufacturing process that involves applying compressive forces to the metal to shape it. The stainless steel 316TI is heated to high temperatures before being subjected to controlled mechanical forces in a forge press or hammer. This process improves the material's mechanical properties, resulting in forged plates Read More

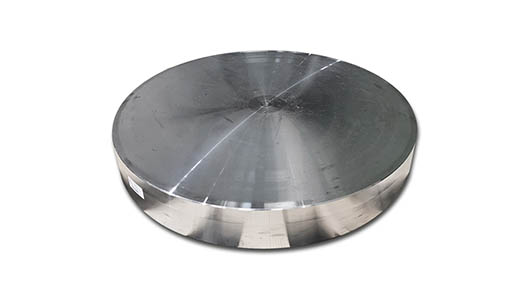

Stainless Steel 316TI Forged Discs

Ferrobend is a well-established manufacturer of high-quality stainless steel products, specializing in the production of 316TI forged discs. The manufacturing process at Ferrobend is designed to ensure the highest standards of quality and precision, with a focus on creating products that meet industry specifications. The process involves several key stages, each crucial for ensuring the integrity and performance of the final product Read More

Stainless Steel 316TI Forged Blocks

Stainless Steel 316TI is an alloy primarily composed of iron, chromium, nickel, and molybdenum, with the addition of titanium, which significantly enhances its resistance to corrosion and high-temperature stability. The inclusion of titanium in 316TI helps to stabilize the steel against the risk of carbide precipitation, which is commonly seen in high-temperature applications. This makes it an ideal material for applications that require high resistance..Read More

Stainless Steel 316TI Forged Flanges

Stainless Steel 316TI Forged Flanges stand out due to their exceptional corrosion resistance, strength, and durability. Manufactured by leading suppliers like Ferrobend, these flanges have become the go-to choice for industries such as petrochemicals, oil and gas, marine, and food processing. This article delves into the details of 316TI forged flanges, their benefits, applications, and why Ferrobend is a trusted manufacturer in this space. Read More

Stainless Steel 316TI Forged Valves

At Ferrobend, every 316TI forged valve is crafted with precision. Using advanced forging techniques and state-of-the-art machinery, Ferrobend ensures each valve meets the highest standards of performance and reliability. The company invests heavily in research and development to continually improve its manufacturing processes and products. Ferrobend sources only the finest Stainless Steel 316TI, ensuring that every valve...Read More