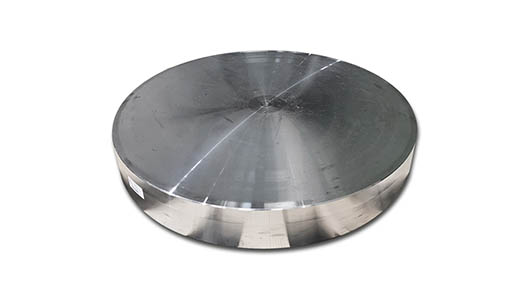

Stainless Steel 316TI Forged Discs

Ferrobend is a well-established manufacturer of high-quality stainless steel products, specializing in the production of 316TI forged discs. The manufacturing process at Ferrobend is designed to ensure the highest standards of quality and precision, with a focus on creating products that meet industry specifications. The process involves several key stages, each crucial for ensuring the integrity and performance of the final product.Quality control is a vital part of Ferrobend's manufacturing process. Each Stainless Steel 316TI forged disc undergoes rigorous testing to ensure that it meets all relevant industry standards. Tests include visual inspections, dimensional checks, and mechanical property assessments, such as tensile strength, hardness, and impact resistance. Additionally, the discs are often subjected to corrosion resistance testing to verify their ability to withstand harsh environments.

Stainless Steel 316TI forged discs manufactured by Ferrobend are the gold standard for industries requiring high strength, corrosion resistance, and reliability. Their unique properties make them indispensable in demanding applications such as aerospace, marine, chemical processing, and more. With Ferrobend’s commitment to quality, state-of-the-art manufacturing processes, and expert craftsmanship, customers can trust that their 316TI forged discs will meet the highest standards of excellence. Whether for a small project or a large-scale industrial operation, Ferrobend ensures that each disc is a product of precision, durability, and unmatched performance.

Stainless steel 316TI forged discs are a critical component in various industrial sectors, from aerospace to marine engineering, automotive, and chemical processing. These discs are known for their exceptional corrosion resistance, high strength, and excellent durability, making them a preferred choice in demanding environments. Ferrobend, a trusted name in stainless steel manufacturing, produces high-quality 316TI forged discs that meet the rigorous standards required for both domestic and international applications. This article delves into the key benefits, manufacturing process, and applications of Stainless Steel 316TI Forged Discs, all while highlighting the expertise of Ferrobend in producing these premium products.

Stainless Steel 316TI is a titanium-stabilized variant of the well-known 316 stainless steel alloy. The inclusion of titanium provides enhanced resistance to sensitization, a phenomenon where chromium carbide forms at grain boundaries and can reduce corrosion resistance, particularly in high-temperature environments. This makes Stainless Steel 316TI especially suitable for applications where high temperature and corrosive environments are present.

316TI forged discs maintain excellent mechanical properties, such as tensile strength and fatigue resistance. These discs are capable of withstanding heavy loads and stresses, making them ideal for high-pressure applications in sectors like aerospace and petrochemical industries.