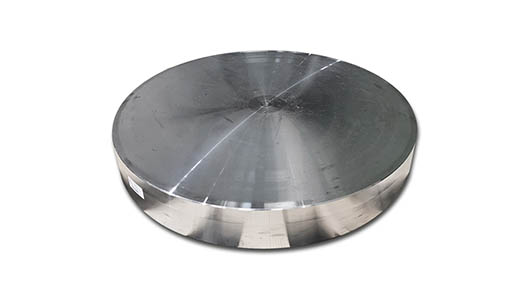

Stainless Steel 316TI Forged Flanges

Stainless Steel 316TI Forged Flanges stand out due to their exceptional corrosion resistance, strength, and durability. Manufactured by leading suppliers like Ferrobend, these flanges have become the go-to choice for industries such as petrochemicals, oil and gas, marine, and food processing. This article delves into the details of 316TI forged flanges, their benefits, applications, and why Ferrobend is a trusted manufacturer in this space. 316TI Stainless Steel is a titanium-modified version of the standard 316 stainless steel. The addition of titanium enhances the material’s resistance to carbide precipitation, making it an ideal choice for high-temperature applications. Stainless Steel 316TI Forged Flanges are manufactured through a forging process, where the steel is shaped under high pressure and heat to create a robust, durable, and high-strength component.

These flanges are used to connect pipes, valves, pumps, and other equipment in a piping system. The forging process results in a stronger structure and improved mechanical properties compared to cast flanges. Ferrobend, a reputed manufacturer, produces 316TI forged flanges with precision and care to ensure that they meet the most stringent industry standards.

316TI stainless steel can withstand high temperatures without losing its structural integrity. This makes it an excellent choice for high-heat applications such as chemical processing, power generation, and refineries. Titanium prevents the formation of carbide precipitation at elevated temperatures, ensuring long-lasting performance.

Stainless steel 316TI is known for its durability, and when used in forged flanges, it offers enhanced service life. These flanges can endure the rigors of heavy industrial use, reducing the frequency of maintenance and replacement.

Ferrobend is a recognized name in the manufacturing of stainless steel forged flanges. With years of expertise in the industry, Ferrobend offers unmatched quality and precision in producing 316TI forged flanges. Ferrobend employs state-of-the-art forging and machining technologies that ensure every stainless steel 316TI flange meets the highest standards of quality and performance. The company uses advanced equipment to create precise, reliable, and durable flanges for a wide range of industrial applications.

Ferrobend understands that each industry has its own set of requirements. Therefore, they offer customizable solutions for stainless steel 316TI forged flanges. Whether you need specific sizes, pressure ratings, or flange types, Ferrobend works closely with clients to deliver a product tailored to their needs.