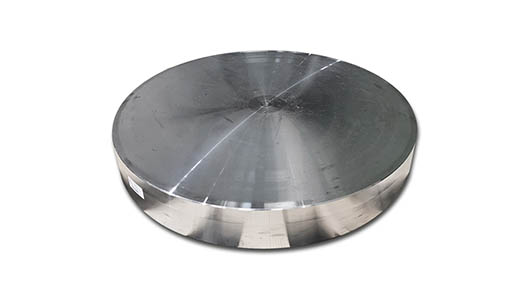

Stainless Steel 316TI Forged Valves

At Ferrobend, every 316TI forged valve is crafted with precision. Using advanced forging techniques and state-of-the-art machinery, Ferrobend ensures each valve meets the highest standards of performance and reliability. The company invests heavily in research and development to continually improve its manufacturing processes and products. Ferrobend sources only the finest Stainless Steel 316TI, ensuring that every valve is made from high-quality, corrosion-resistant material that meets global standards. Their stringent quality control process ensures that every valve is built to last, providing customers with long-term value. Ferrobend understands that no two industrial applications are the same, which is why they offer a range of customizable options for 316TI forged valves.

The 316TI forged valves manufactured by Ferrobend are built to withstand extreme conditions. The titanium alloy’s enhanced resistance to corrosion and high temperatures ensures that these valves maintain their structural integrity over extended periods. This durability minimizes the need for frequent replacements and reduces downtime in industrial operations.

Ferrobend’s stainless steel 316TI forged valves are designed to deliver reliable performance even in the most demanding environments. Whether you are handling corrosive chemicals, high-pressure gases, or extreme temperatures, Ferrobend valves will function efficiently, ensuring the smooth operation of your systems.

Ferrobend ensures that all their products, including 316TI forged valves, meet the international quality standards and certifications required in various industries. From ISO certifications to compliance with standards such as ASME, API, and ASTM, Ferrobend guarantees that each valve meets the necessary regulatory requirements, ensuring safety and quality.

The chemical processing industry deals with highly corrosive chemicals and extreme temperatures. The 316TI forged valves from Ferrobend provide a reliable and long-lasting solution for controlling the flow of chemicals in processing plants. Their resistance to intergranular corrosion ensures that they can handle aggressive substances without failing.